Food synthetic colorants, also known as synthetic edible colorants, are substances produced through chemical synthesis processes used to color food. These colorants can enhance the color of food, improve its sensory appeal, and make it more tempting. The use of synthetic edible colorants is strictly regulated by laws and standards. Domestically, the use of food additives must comply with the "Food Safety Law" and relevant national standards. Based on the GB 5009.35-2023 "National Food Safety Standard - Determination of Synthetic Colorants in Food", RayKol has compiled a comprehensive solution using WAX mixed-mode weak anionsolid phase extraction column, suitable for multi-matrix detection applications.

Fotector Plus high throughput fully automated solid phase extraction instrument

Auto EVA80 high throughput fully automated parallel concentrator

(HPLC) Agilent 1260

RayCure WAX, 150mg/6mL, 30 pieces/box (RC-204-72823N)

Take a mixed standard intermediate solution with a concentration of 50μg/mL, separately measure 4μL, 10μL, 20μL, 40μL, and 100μL into 2mL sampling vials, dilute with water to 1mL, and shake well to obtain the standard series working solutions. The concentrations are 0.2ug/mL, 0.5ug/ml, 1.0ug/ml, 2.0ug/ml, 5.0ug/ml.

Accurately weigh 2g of the sample (accurate to 0.001g), place it in a 50 mL stopper centrifuge tube, first add a suitable amount of water (2 mL-5 mL), heat in a 50°C water bath and mix well, add 25mL of ethanol ammonia solution, vortex for 1min, ultrasonicate or shake (speed ≥250r/min) at 50°C for 20min, centrifuge at 8000r/min for 5 min, transfer the supernatant to a 50mL volumetric flask, repeat the extraction process using 5 mL-10 mL of ethanol ammonia solution each time until the supernatant is colorless, combine the supernatant after centrifugation, and dilute with ethanol ammonia solution to 50mL. Accurately take 10mL of the extraction solution, concentrate with nitrogen at 50°C to about 3mL, dissolve in 10mL of 5% methanol aqueous solution in 2-3 portions as a solution to be purified.

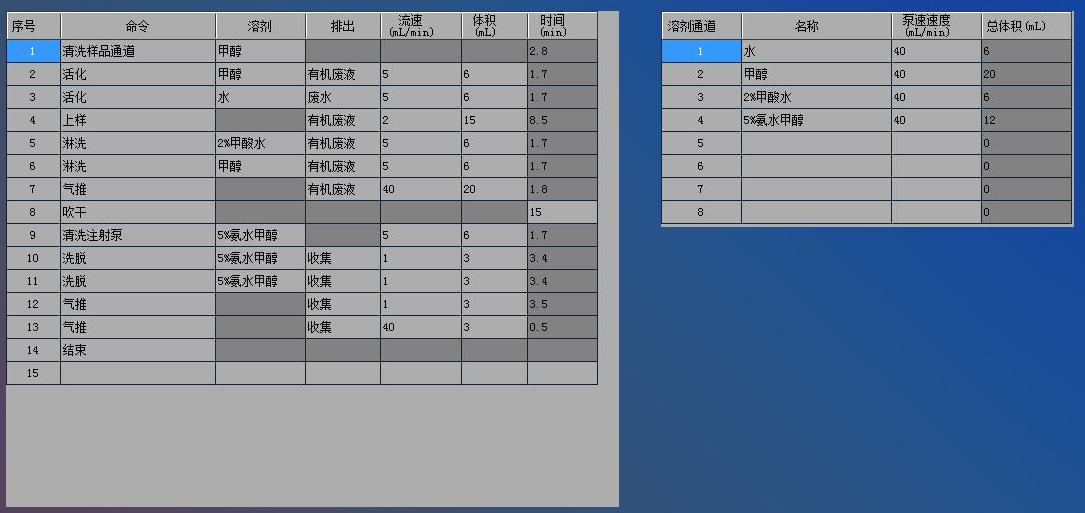

Activation: Sequentially activate the solid phase extraction column with 6mL of methanol and 6mL of water

Sample Loading: Immediately load the extracted solution for purification onto the solid phase extraction column at a flow rate of 2s-3s/drop

Washing: Sequentially wash the solid phase extraction column with 6mL of 2% formic acid aqueous solution and 6mL of methanol, then discard the wash liquid

Drying: Draw dry the column

Elution: Elute with 6mL of 2%-5% ammonia-methanol solution, adding 3mL each time, at a flow rate of less than 2s-3s/drop, collect the eluent

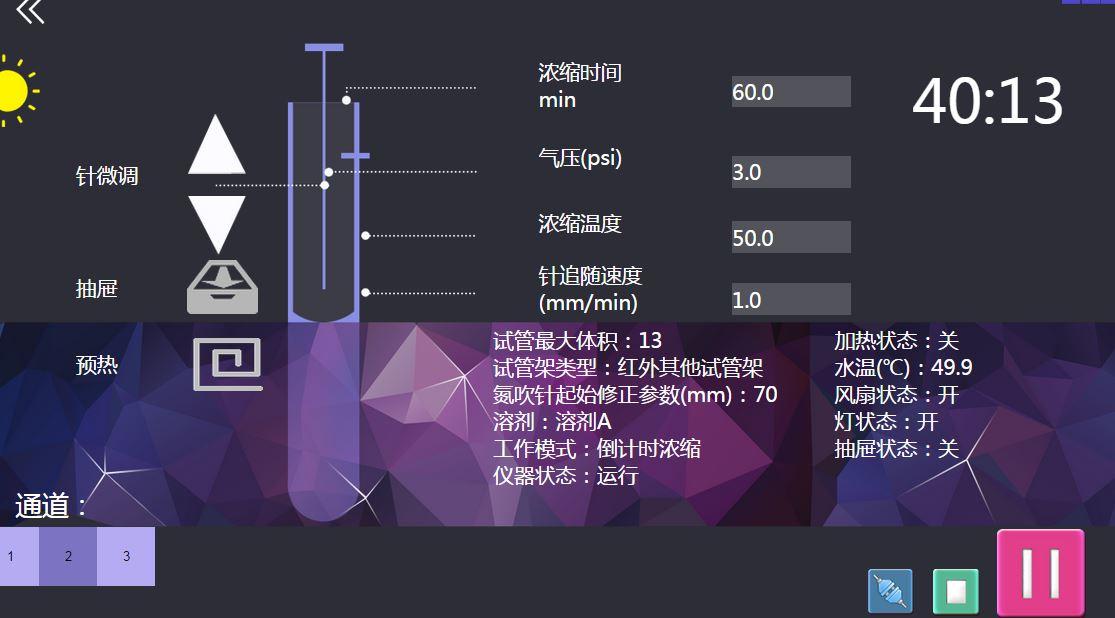

Nitrogen Evaporation: Concentrate with nitrogen at 50°C to near dryness

Redissolution: Accurately add 2mL of ammonium acetate solution (pH=9) to dissolve. The solution is filtered through a 0.45μm aqueous syringe filter, discard 2-5 drops of the initial filtrate, and collect the subsequent filtrate as the test solution

Figure1: Detection of Synthetic Colorants in Food

Solid Phase Extraction Method Fotector Plus Instrument Method Settings

Figure2: Auto EVA Instrument Nitrogen Evaporation Parameters

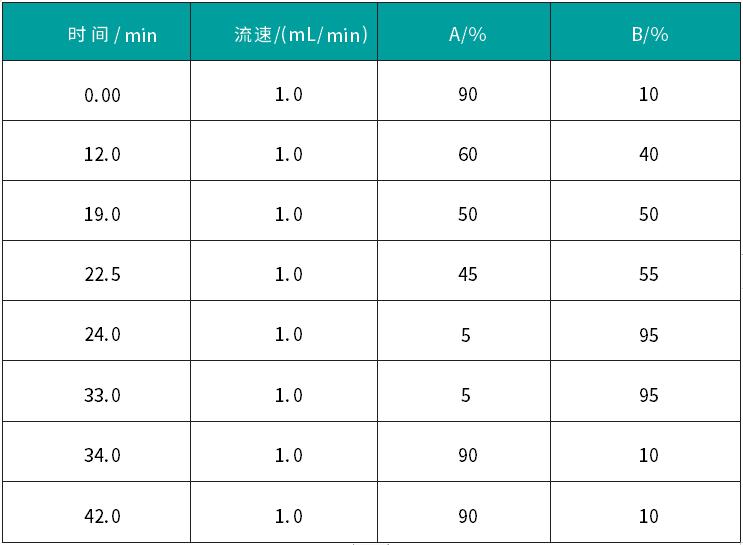

Column: C18 column, 4.6mm×250mm, 5μm, or columns with similar performance

Injection Volume: 10μL

Column Temperature: 30 ℃

Diode Array Detector Wavelength Range: 400nm-800nm, Detection Wavelength:

415nm(Tartrazine, Quinoline Yellow)

520nm(New Red, Amaranth, Carmine, Sunset Yellow, Allura Red, Acid Red and Ponceau 4R)

610nm(Indigo, Brilliant Blue)

Refer to Elution Gradient Table 1, where the mobile phase A is 20mmol/L ammonium acetate solution, Mobile Phase B is methanol

Table1: Reference Elution Gradient

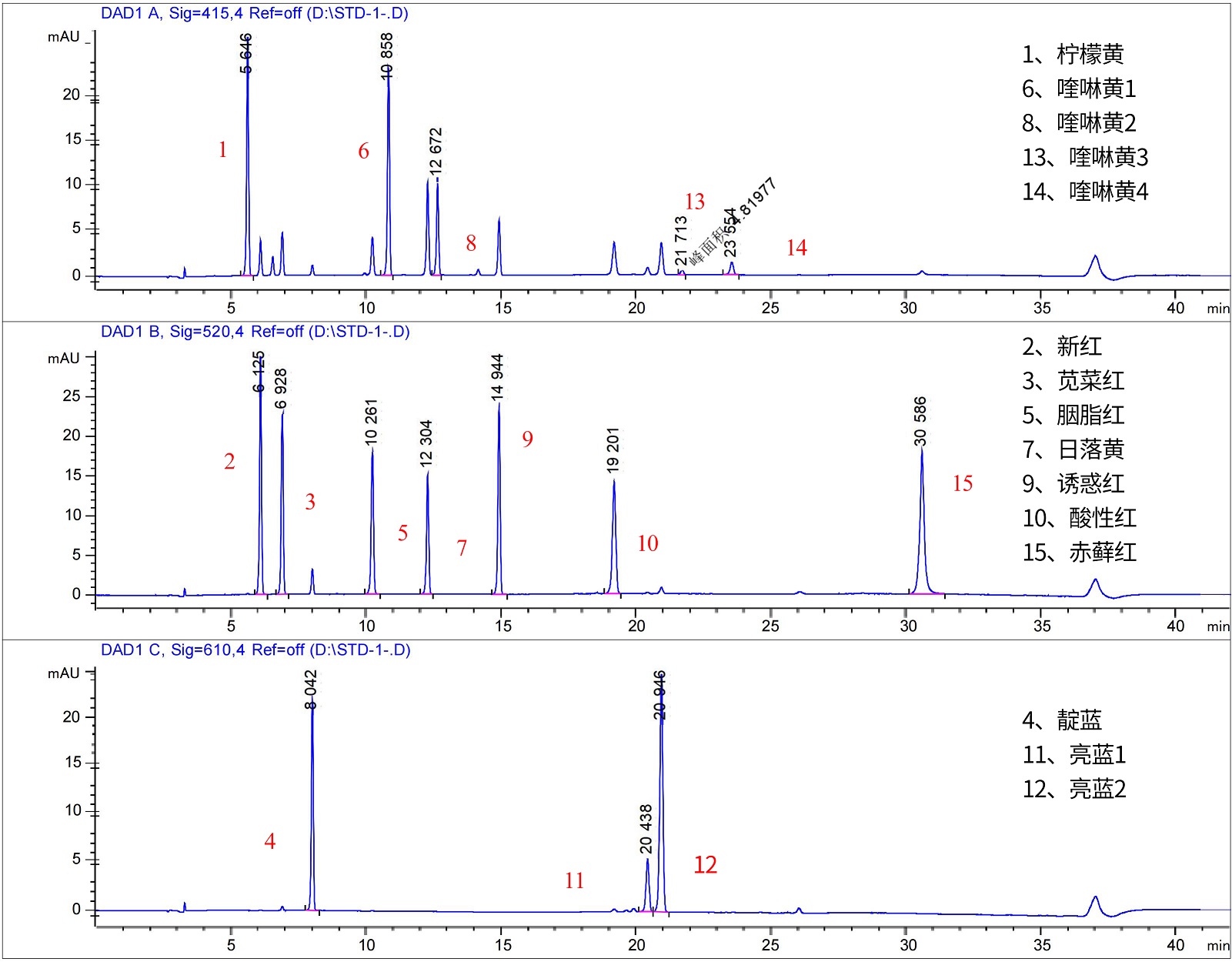

Chromatogram

Figure 3 shows the spectra of 11 synthetic colorant standards (1 μg/mL) at wavelengths of 415 nm, 520 nm, and 610 nm.

Figure3

During the sample extraction process, pay attention to the extraction solution ethanol ammonia water as much as possible before use.

Keep the column moist after activation before use. Adjust the outflow rate after loading to keep it at 2-3 seconds/drop. Too fast is not conducive to the retention of target compounds.

Nitrogen blowing, re-dissolution, and membrane. After purification, the eluent needs to be nitrogen-blown in a 50℃ water bath. During the nitrogen blowing process, it is necessary to pay attention to controlling the nitrogen blowing time to prevent the sample from being completely blown dry, otherwise it will be relatively difficult to re-dissolve. The pH of the re-solution needs to be adjusted to 9. The pH of the re-solution will affect the stability of indigo and the recovery rate of erythrosine. The selection of the filter membrane should also be cautious. Please check whether the filter membrane adsorbs pigments before use.

The extract after sample treatment is purified using the Fotector Plus fully automatic solid phase extractor, saying goodbye to the troubles of large sample volume and manual operation.

The purified eluate is concentrated by the Auto EVA fully automatic parallel concentrator. This process does not require sample transfer and can be directly concentrated. Its design greatly reduces sample loss.