Recently, the Nanjing Institute of Product Quality Supervision and Inspection conducted performance validation and inspection testing on the DRQ Fully Automated QuEChERS Processing Platform produced by RayKol Group (Xiamen) Co., Ltd., confirming that its test results fully comply with technical specifications. Additionally, the inspection institute conducted a detailed on-site review of RayKol Group's production environment, production lines, laboratories, and quality control system, verifying the standardization of its production processes and the stability of its product quality.

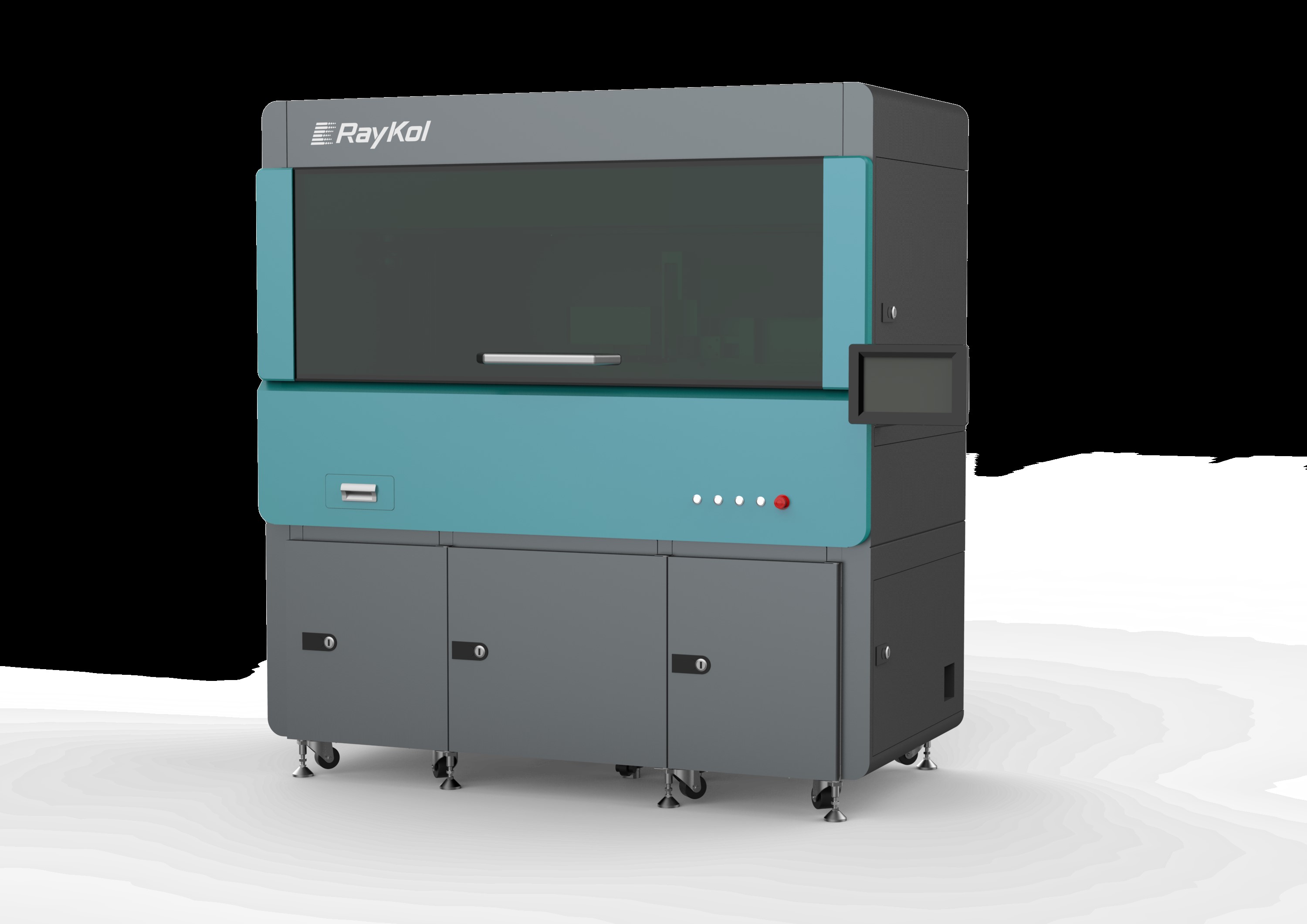

The DRQ Fully Automated QuEChERS Processing Platform is mainly used for the pre-treatment of pesticide residue samples in vegetables and fruits, capable of performing multiple detection processes with unmanned operation. It incorporates several automated features such as automatic sample transfer, addition of extraction solvents, opening and closing caps, and adding salts required for QuEChERS extraction. The instrument strictly adheres to the national standard GB 4793.1-2007 "Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use - Part 1: General Requirements". It has been tested for aspects including appearance quality, marking, functionality, idle operation tests, protection under normal conditions, protective links, anti-electric shock protection, resistance tests, power cords, protection against mechanical hazards, operation protection, and more, with all test results qualifying. The platform boasts advanced design and easy operation, providing users with an excellent experience.

Performance validation projects cover the following areas:

Method establishment and operational processes: The method is simple to operate, with a variety of functional processes. After validation, its convenience has been affirmed.

Manipulator and cap opening/closing module: The manipulator can accurately perform cap selection and opening/closing operations, and its accuracy meets expected standards.

Sample extraction solution addition: The test accurately added 10mL of acetonitrile, and the test results indicated good accuracy and repeatability.

Sample extraction solution switching lines: The test accurately switched lines and added 15mL of acetic acid-acetonitrile, with results also showing good accuracy and repeatability.

Salt module salt tube recognition: The salt module can accurately recognize normal and empty salt tubes, with a success rate of 100%.

Thiamethoxam spike recovery: The recovery rate ranged from 80% to 120%, meeting the recovery rate requirements.

The Nanjing Institute of Product Quality Supervision and Inspection is a comprehensive technical institution under the Nanjing Municipal Market Supervision Bureau. It mainly engages in inspection and testing, standard development, certification technical services, and the transformation of scientific and technological achievements in consumer goods, industrial products, software information technology, and artificial intelligence-related fields. In 2020, it was approved to establish the Nanjing Institute of Quality Development and Advanced Technology Application, formally becoming a municipal scientific research institute in Nanjing.

RayKol Group (Xiamen) is a high-tech enterprise integrating R&D, production, and sales, with products widely used in environmental monitoring and food testing. The company's quality, environmental, health and safety, and intellectual property management systems have all passed international standard certifications. Additionally, the company holds several utility model and invention patents and has received multiple honors and awards. With deep expertise and innovative strength in the inspection and testing field, RayKol introduced the DRQ Fully Automated QuEChERS Processing Platform. In terms of technology, quality, and functionality, it has reached industry-leading positions, earning widespread acclaim and numerous honors and awards, highlighting its strength and responsibility as an industry leader.